The Comprehensive Guide to LiFePO4 Energy Storage Cabinet Pricing, Capacity & Power Configurations

Introduction: The Rise of LiFePO4 for Stationary Storage

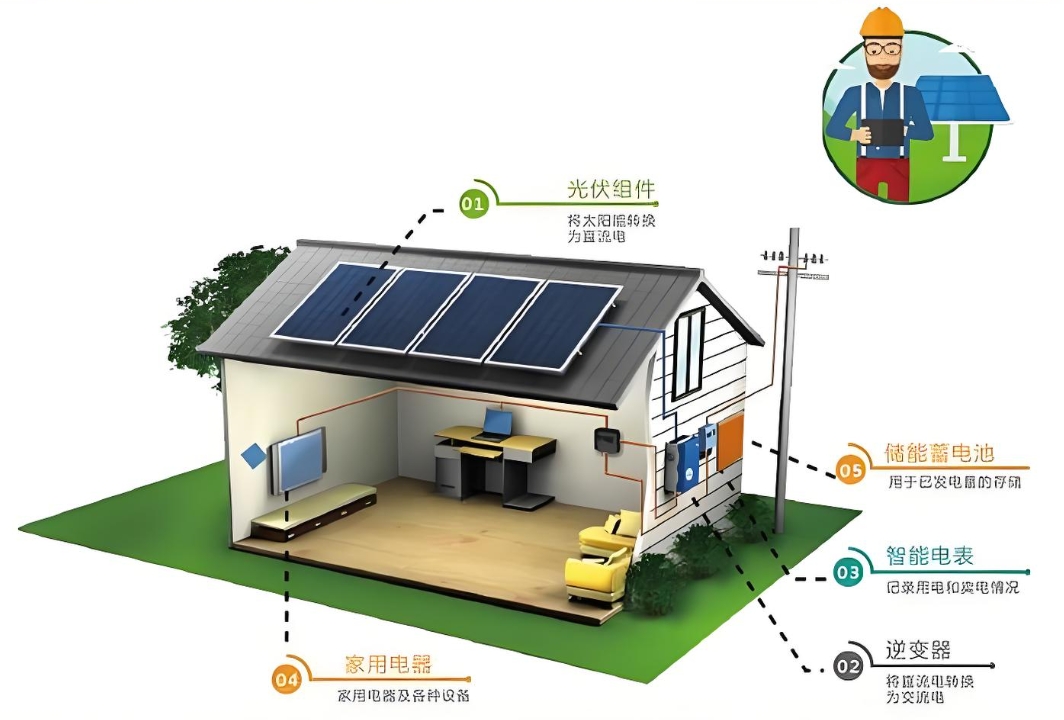

Lithium Iron Phosphate (LiFePO4) battery technology has surged to the forefront of the commercial and industrial (C&I) and utility-scale energy storage market. Renowned for its exceptional safety profile, long cycle life, thermal stability, and decreasing cost trajectory, LiFePO4 is the chemistry of choice for modern energy storage cabinets (ESCs). These pre-engineered, containerized units offer a plug-and-play solution for diverse applications, from peak shaving and backup power to renewable energy integration and grid services. Understanding the interplay between LiFePO4 energy storage cabinet price, capacity (kWh), and power (kW) configurations is crucial for making informed investment decisions. This comprehensive guide explores the key factors influencing cost and how to select the optimal configuration for your needs.

I. Core Concepts: Capacity, Power, and Their Significance

Before diving into pricing, it's essential to grasp the fundamental concepts:

1. Capacity (kWh - Kilowatt-hours):

❁Definition: Represents the total amount of electrical energy the cabinet can store and deliver. Think of it as the "size of the fuel tank."

❁Significance: Determines how long the system can power a load or how much energy it can absorb/generate over a period. Higher capacity supports longer backup durations or greater energy shifting (e.g., storing solar power for evening use).

❁Typical Cabinet Ranges: LiFePO4 cabinets commonly range from relatively small units (e.g., 20-50 kWh) suitable for small businesses or specific equipment backup, through mid-scale units (100 kWh, 200 kWh, 500 kWh) for larger C&I facilities, up to very large containerized systems aggregating multiple cabinets to reach capacities of 1 MWh (Megawatt-hour) or even 10+ MWh for utility projects.

2. Power (kW - Kilowatts):

❁Definition: Represents the rate at which the cabinet can charge (absorb energy) or discharge (deliver energy). Think of it as the "size of the pipe" through which energy flows.

❁Significance: Determines the maximum instantaneous load the cabinet can support during discharge or the maximum rate at which it can charge from a source (like solar inverters or the grid). Higher power is critical for applications needing rapid bursts of energy (starting large motors, providing grid frequency regulation) or for charging/discharging large capacities quickly.

❁Typical Cabinet Ranges: Power ratings align with capacity but are distinct. Common cabinet power outputs range from 50 kW for smaller units up to 250 kW or 500 kW for larger cabinets. Containerized systems integrate multiple cabinets and associated power conversion equipment to achieve MW (Megawatt) scale power outputs.

3. The Crucial Relationship: Capacity (kWh) vs. Power (kW) & C-Rate

These two parameters are independent but intrinsically linked through the ❁C-Rate.

❁C-Rate: A measure of how quickly a battery is charged or discharged relative to its capacity. A 1C rate means a battery can be fully charged or discharged in one hour. A 0.5C rate means it takes two hours.

❁Formula: C-Rate = Power (kW) / Capacity (kWh). Example: A 100 kWh cabinet with a 100 kW inverter has a 1C rating (100 kW / 100 kWh = 1). It can theoretically fully discharge in 1 hour. The same 100 kWh cabinet with a 50 kW inverter has a 0.5C rating (50 kW / 100 kWh = 0.5), taking 2 hours for a full discharge.

❁Impact on Cost & Design: Systems designed for high C-rate applications (like frequency regulation, requiring 2C or higher) often use specialized cells and power electronics, increasing the $/kWh cost compared to a low C-rate system (like overnight solar shifting, typically 0.25C-0.5C) of the same capacity. The power configuration directly influences the required size and cost of the Power Conversion System (PCS - inverter/charger).

II. Key Factors Driving LiFePO4 Energy Storage Cabinet Price

The price of a LiFePO4 ESC is not a simple sticker price; it's a complex equation influenced by numerous technical and market factors:

1. Battery Capacity (kWh): This is the single largest cost component. Price generally scales linearly with usable energy capacity. Cabinets with higher kWh ratings command higher absolute prices. The critical metric is $/kWh.

2. Power Rating (kW) & Power Conversion System (PCS): The required continuous and peak power output significantly impacts cost. Higher kW ratings necessitate larger, more robust inverters/converters (PCS), which are expensive components. Cabinets can be:

❁AC-Coupled: Include the integrated PCS (inverter/charger). Higher upfront cost but simpler integration.

❁DC-Coupled: Deliver DC power only, requiring a separate, external PCS. Lower cabinet base price, but total system cost must include the PCS. Essential for high-voltage DC systems or specific system architectures.

3. Cell Quality & Brand:

❁Tier-1 Manufacturers: Suppliers like CATL, BYD, EVE, REPT, Gotion, Tesla (Megapack) offer cells with proven performance, consistency, longer warranties, and rigorous testing. This commands a significant price premium.

❁Tier-2/Generic Manufacturers: Offer lower upfront costs but may have variations in quality, performance, cycle life, and shorter/less comprehensive warranties. Due diligence is critical.

4. Battery Management System (BMS): A sophisticated BMS is vital for safety, performance, and longevity. Cabinets with advanced BMS features (cell-level monitoring, active balancing, sophisticated thermal management, state-of-health algorithms, cybersecurity) cost more but offer superior protection and insights.

5. Thermal Management System:

❁Air Cooling: Simpler, lower cost, adequate for many moderate-duty applications. Can be less efficient in extreme temperatures.

❁Liquid Cooling: More complex, higher cost, but offers superior temperature uniformity and heat dissipation. Essential for high-power density cabinets, high C-rate applications, or operation in harsh environments. Improves cycle life.

6. Safety & Certifications: Compliance with stringent international safety standards is non-negotiable and adds cost. Key certifications include:

❁UL 9540 / UL 9540A: Safety standard for Energy Storage Systems (ESS) and installations in North America. Crucial for permitting and insurance.

❁UL 1973: Standard for batteries used in stationary applications.

❁IEC 62619: International safety standard for industrial batteries.

❁UN 38.3: Mandatory for transportation safety of lithium batteries.

❁Local Grid Codes: Compliance adds engineering and testing costs.

7. System Integration & Features:

❁Modularity: Cabinets designed for easy capacity expansion via adding modules or units generally cost slightly more per kWh initially but offer long-term flexibility.

❁Enclosure: Robust, weatherproof (NEMA 3R/4/4X or IP55), fire-rated enclosures add cost but are essential for outdoor deployment and safety.

❁Monitoring & Control Software: Advanced cloud-based platforms for remote monitoring, control, performance analytics, and fleet management add value and cost.

❁Grid-Forming Capability: Advanced inverters that can "start" a grid (black start) or operate microgrids independently command a premium.

8. Warranty: Longer and more comprehensive warranties (e.g., 10+ years, guaranteeing 60-70% residual capacity after 6000+ cycles) significantly increase the upfront cost but provide long-term value and risk mitigation. Scrutinize warranty terms carefully.

9. Manufacturer Scale & Reputation: Established, high-volume manufacturers often have better economies of scale and supply chain control, potentially offering better pricing than smaller niche players, though their brand premium remains. Proven track record adds value.

10. Order Volume & Project Scale: Bulk purchases for large projects (multiple cabinets or containerized systems) typically secure significant discounts ($/kWh) compared to single cabinet purchases.

11. Supply Chain & Commodity Prices: Fluctuations in lithium, nickel, cobalt (less relevant for LFP, but still some impact), copper, and aluminum prices, along with global logistics costs, directly impact final cabinet pricing. Geopolitical factors and demand surges can cause volatility.

12. Balance of Plant (BOP) & Installation: While not part of the cabinet price itself, associated costs like site preparation, electrical interconnection, switchgear, HVAC (for indoor), installation labor, permitting, and engineering must be factored into the total project budget.

III. LiFePO4 Energy Storage Cabinet Price Ranges (Mid-2024 Estimates)

Crucial Note: Prices are highly dynamic and subject to rapid change due to technology advancements, manufacturing scale-up, and raw material costs. The figures below are indicative ranges for complete, AC-coupled cabinets (including integrated PCS, BMS, enclosure) from a mix of Tier-1 and Tier-2 suppliers, based on reasonable order volumes. ALWAYS obtain detailed, project-specific quotes.

❁Price per Kilowatt-Hour ($/kWh):

❁Overall Range: $200 - $450 USD / kWh (delivered, before installation/BOP).

❁Tier-1 Premium: Systems utilizing cells from top manufacturers (CATL, BYD, etc.) with full certifications, liquid cooling, and strong warranties typically fall in the $250 - $450 USD / kWh range.

❁Value Tier: Systems utilizing quality Tier-2 cells, air-cooling, standard warranties, and certifications often range $200 - $300 USD / kWh.

❁Economies of Scale: Large containerized systems (1MWh+) can achieve prices towards the lower end or even below $200/kWh for very large utility orders.

❁Estimated Total Cabinet Prices (AC-Coupled Examples):

❁50 kWh / 50 kW (1C): $12,000 - $22,500 USD

❁100 kWh / 100 kW (1C): $20,000 - $40,000 USD

❁100 kWh / 50 kW (0.5C): Lower PCS cost: $18,000 - $35,000 USD

❁200 kWh / 100 kW (0.5C): $36,000 - $70,000 USD

❁200 kWh / 200 kW (1C): $40,000 - $80,000 USD

❁500 kWh / 250 kW (0.5C): $90,000 - $175,000 USD

❁1 MWh Containerized System (e.g., 4x 250kWh units + integration): $200,000 - $350,000+ USD

IV. Matching Configurations to Applications: Optimizing Cost vs. Value

The optimal LiFePO4 ESC configuration depends entirely on the specific use case. Selecting the right balance of capacity and power avoids overpaying for unneeded capability:

1. Solar Energy Time-Shifting / Self-Consumption Optimization:

❁Focus: High Capacity (kWh) relative to daily solar overproduction/load deficit. Store excess daytime solar for use in evening peak.

❁Power (kW) Needs: Moderate. Primarily needs to handle the charge rate from the solar array and the discharge rate to cover the building's typical evening load. C-rates often 0.25C - 0.5C.

❁Price Sensitivity: High focus on $/kWh. Air-cooling often sufficient. Standard cycle life warranties.

2. Peak Shaving / Demand Charge Reduction:

❁Focus: High Power (kW) capability to discharge rapidly and significantly when grid demand (and thus electricity charges) peak. Requires sufficient Capacity (kWh) to sustain the discharge for the typical peak duration (e.g., 2-4 hours).

❁Power (kW) Needs: Must be able to meet or exceed the facility's peak demand threshold. C-rates typically 0.5C - 1C.

❁Price Sensitivity: Focus on $/kW for the discharge capability needed during peaks, balanced with sufficient kWh for duration. Robust BMS/PCS critical.

3. Backup Power / UPS:

❁Focus: Balance between Capacity (kWh) for required runtime of critical loads and Power (kW) to handle the startup surge (inrush current) of large motors (HVAC, elevators) and the continuous load.

❁Power (kW) Needs: Must handle the peak instantaneous load (surge), which can be 2-6x the continuous load for seconds. Continuous kW must match the critical load.

❁Price Sensitivity: High reliability and fast response are paramount. Often justifies Tier-1 components and robust BMS. Runtime (kWh) directly impacts cost.

4. Frequency Regulation / Grid Services:

❁Focus: Very High Power (kW) and extremely fast response times (milliseconds). Capacity (kWh) is secondary but still needed to absorb/deliver energy during regulation events. Requires High C-Rate (2C, 4C or more).

❁Power (kW) Needs: Maximized relative to capacity. Advanced grid-forming inverters essential.

❁Price Sensitivity: High $/kW cost due to specialized cells, high-performance PCS, and liquid cooling. Justified by revenue potential from grid operators.

5. Microgrids & Islanding:

❁Focus: Combination of significant Capacity (kWh) to sustain the islanded load for extended periods and sufficient Power (kW) to handle the connected load, including surges. Often requires Grid-Forming inverters.

❁Power (kW) Needs: Must match or exceed the microgrid's maximum potential load.

❁Price Sensitivity: High system complexity. Justifies investment in reliability, advanced controls, and often Tier-1 components.

6. Electric Vehicle (EV) Charging Support:

❁Focus: High Power (kW) to deliver rapid charging rates to multiple EVs simultaneously without overloading the site's grid connection. Requires sufficient Capacity (kWh) to buffer the energy demand.

❁Power (kW) Needs: Must match the combined peak charging power of the supported EV chargers.

❁Price Sensitivity: Focus on $/kW for the charging power needed. Fast cycle capability important. Liquid cooling often beneficial.

V. The Future Trajectory: Costs, Technology, and Market

❁Continued Price Decline: The $/kWh trend for LiFePO4 is firmly downward, driven by massive manufacturing scale-up (especially in China), process optimization, falling raw material costs (after recent spikes), and technological advancements (higher energy density cells, pack design improvements). Analysts project continued, albeit potentially slower, declines through the latter half of the decade.

❁Technology Evolution: Expect improvements in energy density (more kWh per cabinet footprint), longer cycle life (10,000+ cycles), faster charging capabilities, enhanced safety systems, and smarter BMS/software integration.

❁Market Growth & Diversification: Demand for C&I and grid-scale storage is exploding globally, driven by renewable energy mandates, grid instability, economic incentives (like the US IRA), and falling costs. This fuels further investment and competition.

❁Supply Chain Resilience: Efforts are underway to diversify LiFePO4 supply chains beyond dominant regions, potentially impacting costs and availability in different markets.

VI. Getting Accurate Quotes & Making Your Purchase

1. Define Requirements Rigorously:

❁Application: Be specific (peak shaving, solar shifting, backup, etc.).

❁Required Usable Capacity (kWh): Based on energy needs/load profiles.

❁Required Continuous & Peak Power (kW): Based on load analysis, including surge currents.

❁Voltage: AC output (e.g., 480V 3-phase) or DC (if DC-coupled).

❁Certifications: Mandatory for your region (UL, IEC, etc.).

❁Environmental Conditions: Ambient temperature range, indoor/outdoor, seismic zone.

❁Warranty Expectations: Duration, cycle/throughput guarantees, end-of-life capacity.

❁Integration: AC-coupled (preferred for simplicity) or DC-coupled?

❁Monitoring/Control Needs: Required software features.

2. Research Reputable Suppliers: Look for manufacturers with:

❁ Proven track record and project references.

❁ Comprehensive certifications (UL 9540, UL 1973, IEC 62619).

❁ Strong technical support and local service (if needed).

❁ Transparent warranty terms.

3. Request Detailed Proposals (RFPs): Provide your requirements clearly. Ask for:

❁ Itemized pricing for the cabinet(s) and any essential BOP.

❁ Detailed specifications (cell manufacturer, BMS features, cooling type, PCS specs, cycle life, DoD, efficiency, dimensions, weight).

❁ Warranty documentation.

❁ Projected performance data.

❁ Drawings and installation manuals.

4. Compare Holistically: Don't just compare $/kWh. Evaluate:

❁ Total cost of ownership (including efficiency losses, expected lifespan).

❁ Quality and reputation of core components (cells, PCS).

Suitability of the proposed configuration for your specific❁ application.

❁ Strength and clarity of the warranty.

❁ Supplier reliability and support capabilities.

5. Consider Professional Engineering: For complex installations or large systems, consulting with an energy storage engineer can optimize design, ensure code compliance, and prevent costly mistakes.

Conclusion: Investing Wisely in LiFePO4 Storage

LiFePO4 energy storage cabinets represent a powerful and increasingly cost-effective solution for a wide range of energy management challenges. While the upfront LiFePO4 energy storage cabinet price is a significant consideration, it's vital to understand that this price is intricately linked to the capacity (kWh) and power (kW) configuration required for your specific application. By carefully defining your needs, understanding the key cost drivers, and diligently evaluating proposals based on total value (not just lowest $/kWh), you can make a sound investment that delivers long-term economic and operational benefits through enhanced energy resilience, reduced costs, and support for a sustainable energy future. The market is dynamic, so stay informed, get multiple quotes, and partner with reputable suppliers to navigate your energy storage journey successfully.